Adhesive Peel Tester commercial|adhesive peel strength : member club ASTM D903 is a common test performed for determining the strength of adhesive . Seja bem-vindo a Neo. Você possui uma conta? Lembrar acesso

{plog:ftitle_list}

17 de out. de 2023 · Então entra agora mesmo no Grupo de Whatsapp de Whatsapp SENSI VIP. O Grupo de Whatsapp de Whatsapp de whatsapp SENSI VIP é o local ideal pra encontrar pessoas com as mesmas paixões por Games e Jogos! Login; Crie uma conta grátis! Adicionar Grupo! Toggle navigation. Início; Blog; Categorias;

ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to as the “T-Peel” test because the .The ADMET eXpert 7601 adhesive and peel testing system has been designed to .ASTM D903 is a common test performed for determining the strength of adhesive .The ADMET eXpert 7601 adhesive and peel testing system has been designed to allow users to perform a wide variety of adhesive tests on a single easy to use and compact instrument.

ASTM D903 is a common test performed for determining the strength of adhesive bonds. In the following procedures, a piece of tape or adhesive is bonded to a standard material and peeled backwards at a 180 degree angle.ASTM D903 is a standard test procedure developed in accordance with international standards to determine the comparative peel or stripping characteristics of adhesive bonds. ASTM D903 .

ASTM D3330 Test Methods. ASTM D3330 includes six distinct test methods (A-F) to evaluate different types of peel adhesion. Here’s an overview: Method A – Measures 180° peel .ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide variety of applications in an even wider range of industries. Some examples of materials .

Peel testing is critical for evaluating the seal strength of various adhesive bonds. Some bonds, such as those that seal consumer packaging, are intended to be break at low forces, while others, such as those used in automotive .ASTM D3330 is a major peel testing standard that outlines the requirements for determining the peel adhesion properties of pressure-sensitive tapes such as surgical, electrical, packing, and duct tape. The standard includes 6 different .Qualtech Products Industry Peel Tester is an Automatic Peel Tester for flexible bonded to rigid test specimen to measure the Adhesive Strength of a wide range of samples at the touch of a button including adhesives.

A peel adhesion tester is a specialized instrument designed to measure the adhesive strength of materials, including tapes, labels, films, and other packaging components. It simulates real-world scenarios by applying a .Adhesive Peel Tester is a Tensile Tester specifically designed to perform the following : 180° Adhesive Peel Test. 90° Adhesive Peel Test. Loop Tack Test. Roll Peel Test. Release Force Test of Silicon Liners; Suitable for : PSA Tapes and Labels. Confirms to : PSTC 101 / PSTC 16 / PSTC 8 / ASTM D 3330ChemInstruments offers a wide range of adhesive and release testers including the AR-1000, Peel Adhesive Testing Machines, Release Machines and Unwind Machines for use in adhesive testing laboratories. Toggle menu. Search. .

The data we provide assists material engineers in the selection of materials in global markets. It includes adhesive strength testing such as tensile, shear, and peel data, as well as other adhesive property tests (e.g., impact, odor, and aging). Testing can be performed in hot/wet/dry conditions at ambient, elevated, or reduced temperatures.Get precision measurements for 90° peel tests with the ChemInstruments 90° peel adhesive testing machine. The 90° peel adhesive tester runs at varying speeds for added flexibility and offers a number of additional features. Toggle menu. Search. View Quote; . 510 Commercial Drive - Fairfield, OH 45014

The ADMET eXpert 7601 adhesive and peel testing system has been designed to allow users to perform a wide variety of adhesive tests on a single easy to use and compact instrument. You can confidently report results knowing that the system has been engineered to meet all accuracy requirements specified in major standards organizations including .

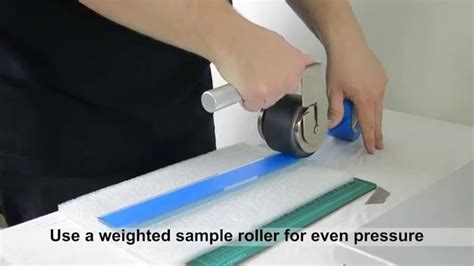

ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing standards such as ASTM D1781, ASTM D3330, ASTM D3167 and can also be customized based on your test application. Below we will explore the types of peel tests .According to ASTM D3330, specimens for the peel test must be prepared from pressure-sensitive tape of a specific size in order to measure the peel adhesion. The exact dimensions of the specimens vary according to the test method within the standard. In general, however, the specimens must be cut to meet the specified width and length requirements to ensure . 180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle.

astm d903 peel test

Cut and peel testing. Cataplasma testing – This is similar to the ‘cut and peel’ test process, but still not exactly the same. This test will put the adhesive through a similar climate in which the end-product will likely be exposed. So, let’s say a caravan will be used in Canada.

There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, coatings, and other bonded materials. There are three main types of peel tests including 90 degree peel test, 180 degree peel test, and a T-Peel test. The LoopAdhesion testing after the coating process will quantify the strength of the bond between substrate and coating, or between different coating layers or the cohesive strength of some substrates. Routine adhesion tests are used as part of inspection and maintenance procedures to help detect potential coating failures.A peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).

Adhesives and Peel Testing Samples were prepared by direct coating the specified adhesive on 2 mil PET facestock and drying for 5 minutes at 80°C in a forced air oven. The target coating thickness for the adhesives was approximately 1 mil (~25 µm). The samples were covered with release liner and allowed to condition in a controlled

With each of the mechanisms of adhesion playing a role in performance, adhesion scientists investigate the strength of an adhesive bond to determine its ability to perform in an application.. Measuring the “work of adhesion” for a given bond helps to determine the strength of an adhesively bonded assembly. The most common way to measure this is to pull an adhesive .Get quotation from a top manufacturer and supplier of peel, seal, bond, and adhesion strength test equipment. +91 9313 140 140 . [email protected]. . Instruments fill the form with requirements . For structural adhesives the T-peel test is most often quoted. Figure 6: Floating roller and climbing drum peel tests . . There are commercial instruments available .Adhesive Testing Equipment . A wide array of adhesives is used as a bonding agent for composites. Therefore, they need to be tested adhesion before a product can be used. . ISO 8510 -- Adhesives -- Peel test for aflexible-bonded-to-rigid test specimen assembly ;

A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel Adhesion-Face Stock test method. In addition, as the need to compare test results from other parts of the world increases, it is important to be .The most versatile peel tester on the market, the ChemInstruments Adhesion/Release testing machine with digital display is designed to perform PSTC, ASTM, TLMI, FINAT, and AFERA adhesion and release testing procedures. . ChemInstruments - 510 Commercial Drive - Fairfield, OH 45014

Benefits of Peel/Seal/Bond and Adhesion Strength Tester. The Presto Adhesion Strength Tester serves the purpose of measuring the enduring adhesion or peelability of self-adhesive pressure-sensitive materials. Peel adhesion, in this context, refers to the force needed to remove a pressure-sensitive coated material from a standard test plate under specified conditions, at .

Testing Equipment for Peel Adhesion. A multi-functional peel tester is used to evaluate the peel force in different peel angles, rates, and temperatures (Figure 1). The peel tester is capable of evaluating independent parameters of peel rate from 15-300 cm/min, angle from 0° to 180°, and temperature (by a Commercial styrenic block copolymer-based adhesives can exhibit high peel force cohesive failure at standard test speeds when bonded to high-energy substrates like polished steel. 2.4.3 Shear The shear holding power of pressure sensitives is low in comparison to other adhesives due to their softness and low strength.

astm d1876 peel strength

Test Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .

PSTC-101 is a standard test method to measure peel adhesion strength in pressure s. FTM-9 Pressure Sensitive Tape Loop Tack Test Equipment. Loop tack tests provide the means of assessing the most important and yet the hard. ASTM D903 180 degree Peel Strip Strength of Adhesive Bonds. ASTM D903 is a standard test procedure to determine the .Peel testing of adhesive and pressure sensitive tapes is used for quality assurance, and provides a means of assessing uniformity of the adhesion of a given type of tape. The assessment may be within a roll of tape, between rolls, or between production lots. Adhesive properties for tapes are measured using a standard test surface, a specified angle and test . A wide range of adhesive properties can be measured by applying tensile or compression forces in a controlled manner. Figure 1. Single- and Twin-Column Materials Testing Machines Figure 2. Test Jig Showing 90. Peel Test on a Pressure-Sensitive Barcode Label Materials testing machines provide a powerful way of evaluating adhesive performance. A .

To determine T-peel strength, the ISO 11339 test standard can be applied for product optimization. Testing and Simulation of T-Peel Strength . Knowing the force required to progressively separate two bonded, flexible adherends gives engineers an understanding of the direct measure of the adhesive bond strength in a bonded joint.

The death of teenager Nex Benedict a day after a fight in an Oklahoma school toilet has drawn national attention as vigils take place around the US. A police investigation into .

Adhesive Peel Tester commercial|adhesive peel strength